Tensile Strength in Rubber Products

Tensile strength is a fundamental property of rubber materials that measures their ability to resist breaking or deformation under tension. The tensile strength of rubber has a direct influence on its mechanical performance and overall durability. Rubber with high tensile strength is crucial for applications where mechanical strength, durability, and resilience are required.

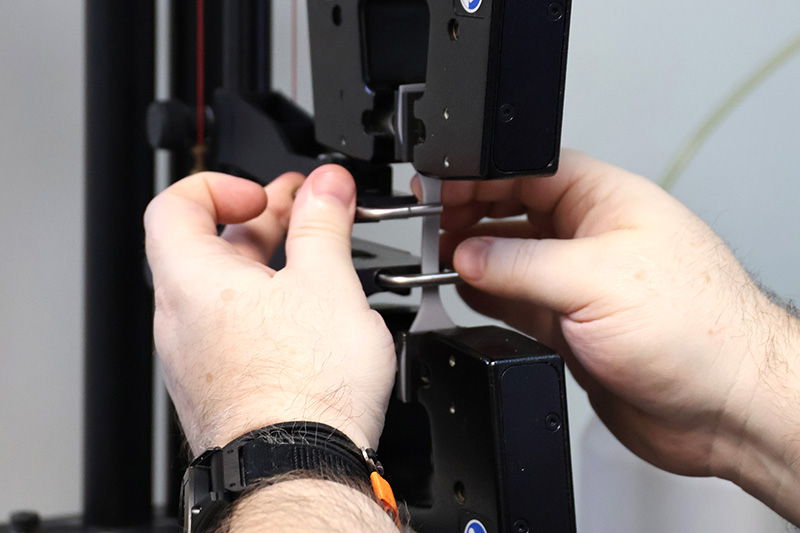

The process of evaluating tensile strength involves subjecting a rubber sample to a precisely controlled and gradually increasing tension force until failure occurs. At Mosites Rubber, we carefully test all of our rubber products to ensure that they meet their strength and durability requirements.

Effects of Tensile Strength on Rubber Performance

- Resistance to Breaking: Rubber materials with high tensile strength exhibits exceptional resistance to breaking or tearing when subjected to stretching or pulling forces. This is particularly important in applications where rubber components experience significant mechanical stress.

- Flexibility and Elasticity: Rubber with appropriate tensile strength maintains its flexibility and elasticity, allowing it to stretch and return to its original shape without permanent deformation. This property is essential for applications that require repeated or dynamic stretching.

- Load-Bearing Capability: Rubber products with higher tensile strength can bear heavier loads without experiencing significant deformation or failure. This makes them suitable for applications where weight-bearing capacity is critical.

- Tear Resistance: Rubber with high tensile strength demonstrates improved resistance to tearing or propagation of cracks, enhancing the longevity and reliability of the rubber components.

Industry Applications

High tensile strength rubber finds applications across numerous industries where mechanical strength is essential. Some key areas where rubber with exceptional tensile strength excels include:

- Automotive: Tire treads, belts, hoses, engine mounts, and suspension components that require robust tensile strength to withstand mechanical stress and vibration.

- Construction: Seals, gaskets, and weatherstripping used in building construction and infrastructure projects, where tensile strength ensures longevity and performance under various environmental conditions.

- Industrial Equipment: Conveyor belts, O-rings, seals, and bushings used in heavy machinery and equipment, where tensile strength enables reliable operation under demanding conditions.

- Medical Devices: Rubber components in medical devices, such as gloves, surgical instruments, and tubing, where high tensile strength is crucial for ensuring safety and reliability.

- Aerospace: Rubber with high tensile strength can be employed in a variety of aerospace applications, such as vibration and shock dampening in engine mounts, or in wire and cable management to provide support and protection for cabling.

Choosing the Right Tensile Strength Rubber

Selecting the appropriate rubber with the desired tensile strength is vital for achieving optimal performance and durability. Factors to consider include the specific application requirements, operating conditions, expected mechanical stress, and regulatory standards.

For more information on rubber tensile strength, or assistance in selecting the right rubber material with the desired tensile strength, please contact our knowledgeable team. We are dedicated to providing high-quality rubber solutions with exceptional tensile strength to meet your unique needs.