Rubber Products in Metal Forming

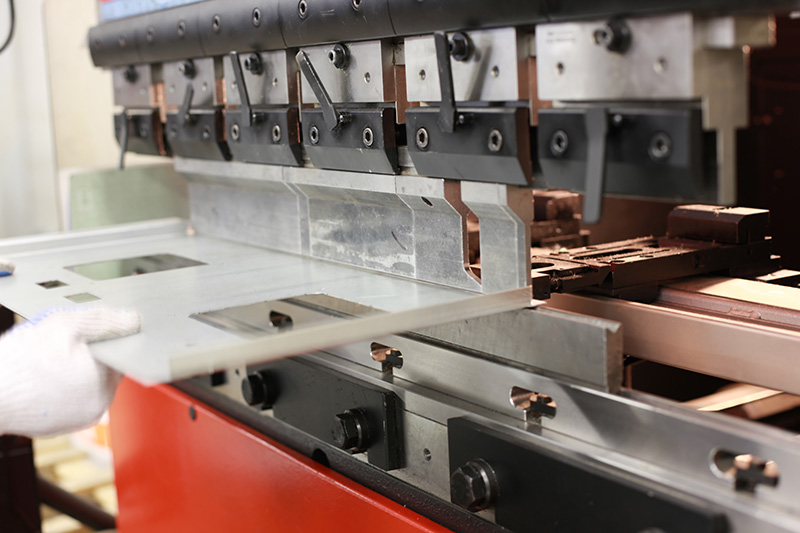

Rubber products play a vital role in the metal forming industry, offering unique properties that enhance precision, protect surfaces, and optimize overall performance. One of the primary uses for rubber in metal forming is to provide cushioning and protection of equipment during the forming process.

Mosites Rubber understands the unique challenges and requirements of the metal forming industry. With our expertise in manufacturing high-quality rubber solutions, we offer a range of products specifically designed to optimize metal forming processes. Our rubber products find diverse applications in metal forming, contributing to improved efficiency, precision, and overall productivity.

Our Metal Forming Products

Our extensive range of rubber products for metal forming include press pads and more. These products are carefully engineered and manufactured to meet the demanding needs of the metal forming industry. Additionally, we offer specific products tailored for various metal forming applications, such as:

- Hydroforming: Our rubber solutions for hydroforming applications provide effective sealing, cushioning, and support during the hydroforming process, ensuring optimal results.

- Wear Pads: Our wear pads are designed to protect metal surfaces from friction and wear, extending the lifespan of tools and dies used in metal forming operations.

- Tray Pads: Tray pads offer excellent cushioning and protection for delicate metal components during handling and transportation within the metal forming process.

- Drop Hammer Pads: Our drop hammer pads are engineered to withstand high impact forces, providing reliable support and cushioning during drop hammer forging operations.

- Bladder Repair: We offer bladder repair solutions that help restore and extend the life of bladder systems used in metal forming applications, minimizing downtime and maintaining productivity.

Advantages of Mosites Rubber Metal Forming Solutions

By choosing Mosites Rubber as your metal forming rubber solutions provider, you benefit from:

- Industry Expertise: With decades of experience in the rubber industry, we possess a deep understanding of the metal forming sector’s unique challenges and requirements.

- High-Quality Materials: We utilize premium rubber compounds that are engineered for durability, wear resistance, and performance in demanding metal forming environments.

- Customization and Engineering Support: Our team works closely with metal forming professionals to design and manufacture custom rubber products that meet specific application requirements, ensuring optimal performance and productivity.

- Reliable and Timely Delivery: We prioritize prompt order fulfillment and delivery to minimize downtime and keep your metal forming operations running smoothly.