Electrical Conductivity in Rubber

Electrical conductivity in rubber refers to its ability to allow the flow of electrical current. Rubber materials can be made electrically conductive by incorporating conductive fillers, such as carbon black or metal particles, into the rubber matrix. These fillers create a conductive network that facilitates the movement of electrical current through the rubber material. The production of electrically conductive rubber involves a carefully controlled manufacturing process that combines rubber polymers with conductive fillers to achieve the desired electrical conductivity.

Electrically conductive rubber offers unique capabilities, combining the flexibility, resilience, and sealing properties of rubber with the ability to conduct electricity, allowing for a wide variety of uses.

Manufacturing Process

- Rubber and Filler Selection: Suitable rubber polymers and conductive fillers are chosen based on the desired electrical conductivity and mechanical properties.

- Compounding: The rubber polymers and conductive fillers are mixed together in precise proportions to achieve the desired electrical conductivity levels.

- Mixing and Dispersion: The compounded rubber and filler mixture undergoes mixing to ensure uniform distribution of the conductive filler throughout the rubber matrix.

- Shaping and Forming: The conductive rubber compound is shaped into the desired product form using methods such as extrusion, compression molding, or injection molding.

- Vulcanization: The shaped rubber product is exposed to heat and pressure or treated with a curing agent to enhance its mechanical properties and stability.

- Finishing and Quality Control: The final product undergoes trimming, inspection, and testing to ensure it meets the required electrical conductivity specifications and quality standards.

Industry Applications

Electrically conductive rubber finds applications in a wide range of industries where electrical conductivity is required.

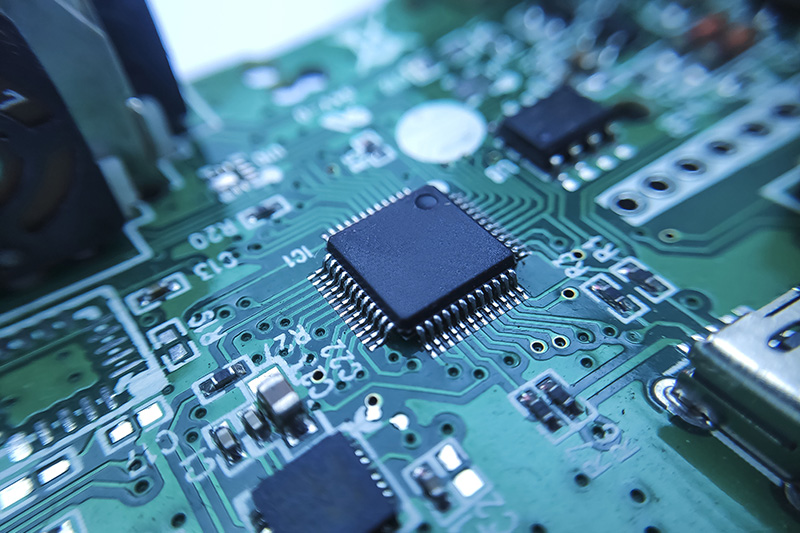

- EMI/RFI Shielding: Electrically conductive rubber provides a conductive barrier that prevents the transmission of electromagnetic waves, protecting sensitive electronic components from interference and ensuring reliable performance.

- Static Dissipation: Electrically conductive rubber helps dissipate static charges and prevents electrostatic discharge (ESD), which can damage sensitive electronic devices or pose a safety risk in explosive or flammable environments.

- Electrical Connectors and Contacts: Electrically conductive rubber is used to ensure reliable electrical connections. It provides a compliant interface that accommodates variations in mating surfaces, while simultaneously maintaining good electrical conductivity.

- Heating Elements: Electrically conductive rubber can be designed as heating elements for applications such as heated mats, automotive seat warmers, and medical devices. The conductive rubber generates heat when an electrical current passes through it, providing efficient and uniform heating.

Choosing the Right Electrically Conductive Rubber

Selecting the appropriate electrically conductive rubber for a specific application is essential for optimal performance and reliability. Factors to consider include the required level of electrical conductivity, environmental conditions, mechanical properties, and compatibility with other materials or substances.

For more information on electrically conductive rubber, its benefits, applications, or assistance in selecting the right electrically conductive rubber material for your specific needs, please contact our knowledgeable team. We are dedicated to providing high-quality electrically conductive rubber solutions to meet your unique requirements.